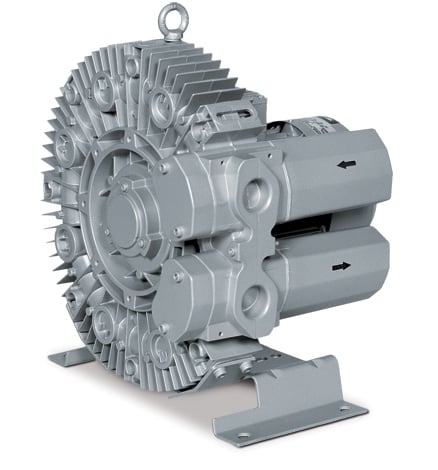

Elmo Rietschle's G-Series

Side Channel Regenerative Blowers

When it comes to reliable side channel regenerative blower technology, Pinnacle Industries is commitment to providing our customers with only the highest in quality and value. Elmo Rietschle solutions are just that; built to last. The Elmo name is rich in history with the Elmo Rietschle side channel regenerative blower being the original Siemens regenerative blower. The G-Series blowers have proven their nearly maintenance-free reliability over many decades.

Elmo Rietschle side channel regenerative blowers are used in all types of industrial and wastewater treatment application for conveying gases and gas-air mixtures. Even at high differential pressures, side channel blower reliability is achieved and ensured by bearings arranged outside the compression chamber. G-Series side channel regenerative blowers see contact-free compression with the impeller mounted directly on the motor shaft.

As a regenerative blower distributor, Pinnacle Industries sees the value of the high quality manufacturing and materials of Elmo Rietschle. The G-Series side channel regenerative blowers provide long life with minimal service along with noise and temperature levels lower than most other vacuum pumps and compressors. G-Series machines are available in a wide selection ranging up to 1,766 cfm at 60 Hz and differential pressures up to 420 in. water for high performance in demanding applications.

Advantages:

- Reliable and built-to-last, virtually maintenance-free

- German engineered for high quality

- Robust yet light-weight

- For use worldwide (UL/CSA/IEC/EN approval)

- 50/60 Hz voltage range motors

- ATEX 94/9 EG

- Adjustable speed via external or integral converters

- Single stage and two stage models available

- Largest selection of size and models available

Applications Vacuum and/or Pressure:

- Aeration and wastewater treatment

- Drying out buildings

- Fishpond aeration

- Food & Beverage

- Industrial vacuum cleaners / central extraction systems

- Dental vacuum

- Letter sorting / enveloping

- Packaging

- Printing & Paper

- Pneumatic conveying

- Soil treatment

- Swimming pool technology / jacuzzis hot tub aeration

- Textile

- Vacuum Thermoforming

- Robot automation / pick up and place

- Labeling Machines

- Airknife drying systems

- Dessicant dryer tank air circulation

- Concrete silo aeration and conveying

G-Series Vacuum Pumps

Operating Principle G-Series

The impellers in the G-Series side channel blowers are mounted directly on the motor shaft for contact-free compression. Maximum operational reliability, even at high differential pressures, is ensured by the arrangement of the bearings outside the compression chamber.

The gas is taken in through the inlet. As it enters the side channel, the rotating impeller imparts velocity to the gas in the direction of rotation. Centrifugal force in the impeller blades accelerates the gas outward and the pressure increases.

Every rotation adds kinetic energy, resulting in further increase of pressure along the side channel. The side channel narrows at the rotor, sweeping the gas off the impeller blades and discharging it through the outlet silencer where it exits the pump.

G-BH 8

With it’s compact design the G-BH is about half as large (installed volume) and nearly 60% lighter than a comparable standard machine with the same performance characteristics. Quiet, modern sound engineering makes it only half as loud (78 db(A) versus 84 db(A)). The BH8 cuts costs in shipping (low weight), packaging (smaller), electrical installation (smaller cross sections and smaller circuit protection devices), and electrical energy (high efficiency and good controllability). These units are normally operated with frequency converters. The housing components can be rotated in 45° increments without manifolds and silencers or in 90° increments with manifolds and silencers. Together, both of these features offer maximum flexibility upon integration in the overall system.

Features:

- Volumetric flow up to 950 m³/h

- Differential pressure −550 mbar

- Small design volume

- Low weight

- Energy-saving operation

- Variable electronic speed control

- Intrinsic safety built in

- Energy-saving operation through higher efficiency

- Variable output control

- Noise reduced by half

- Pulsation-free compression

- Virtually maintenance-free

Volume flow:

- up to 950 m³/h

- up to 558,8 cfm

G-BH1

With their high inlet volume flow (up to 2,450 m³/h) and a differential pressure of up to -480 mbar), our low noise G-BH1 all-rounder have earned their reputation and convinced thousands of customers all over the world. They are reliable, low-maintenance and durable and are the first choice for many applications in mechanical engineering.

When used with a frequency converter the performance of the G-BH1 pumps and compressors can be increased considerably. The G-BH1 machines are UL/CSA approved and can be used without further testing all over the world. Motors comply with DIN EN 60034 and have IP 55 protection. Available at short notice or ex stock and also as ATEX certified models, it is a classic that has proven its innovative quality. Needless to say, only those materials are used which comply with the requirements of the RoHS.

Volume flow:

- 50 to 2,450 m³/h

- 29.4 to 1,441.2 cfm

G-BH1 00

The smallest side channel blower on the market. With a height and width of approx. 125 mm and a depth of approx. 60 mm, the G-BH1 00 blowers have the size of a CD and are the smallest gas ring vacuum compressors available on the market. Furthermore, the adjustable volume flow of the machines ensures that only the exact performance required is actually being supplied – not more.

These blowers are employed primarily in fine mechanical and medical technology applications. With their robust and built-to-last design, they are also used in other industries such as mechanical engineering. The G-BH1 00 is driven via an electronically commuted DC motor. This guarantees a high level of efficiency and maintenance-free operation for more than 20,000 operating hours. The operating electronics are a standard feature of the machines which allow infinitely variable control of speed and output of the blower.

Volume flow:

- 21 to 35 m³/hr

- 12.4 to 20.6 cfm

G-BH2

Series G-BH2 machines are equipped as standard with highly efficient drive motors (efficiency class 1 – eff1), which also feature multi-frequency and wide voltage range coils permitting use throughout the world on wide ranging mains power supplies and the operation of frequency converters up to 100 Hz (6000 rpm).

By using the VELOCIS, you will protect the environment and save money.Needless to say, only those materials are used which comply with the requirements of the RoHS.

Volume flow:

- 330 to 850 m³/hr

- 194.1 to 500 cfm

G-BH7

Our revolutionary G-BH7 side channel blowers can create pressure differences of up to 1,000 mbar — more than any other gas ring compressor! So far, the systems used to reach these differential pressure ranges were much louder and larger — or subject to wear. Now the advantages of wear-free operation coupled with a low noise level can also be used in the most demanding applications. The G-BH7 vacuum pumps and compressors can work up to 20,000 hours without maintenance down time. These specialist machines have proven their reliability under the harshest of conditions. Their noise level was already impressively low, but our engineers and designers were able to make them even more quiet.

The use of a frequency converter mounted directly to the motor or installed separately in a switchgear cabinet can considerably increase compressor capacity without an increase in size. Speeds of up to 6000 rpm (100 Hz) can be achieved with standard machines. Needless to say, only those materials are used which comply with the requirements of the RoHS. Furthermore, these machines can be supplied without delay and are also available in ATEX certified form.

Volume flow:

- 50 to 230 m³/hr

- 29.4 to 135.3 cfm

Contact Us