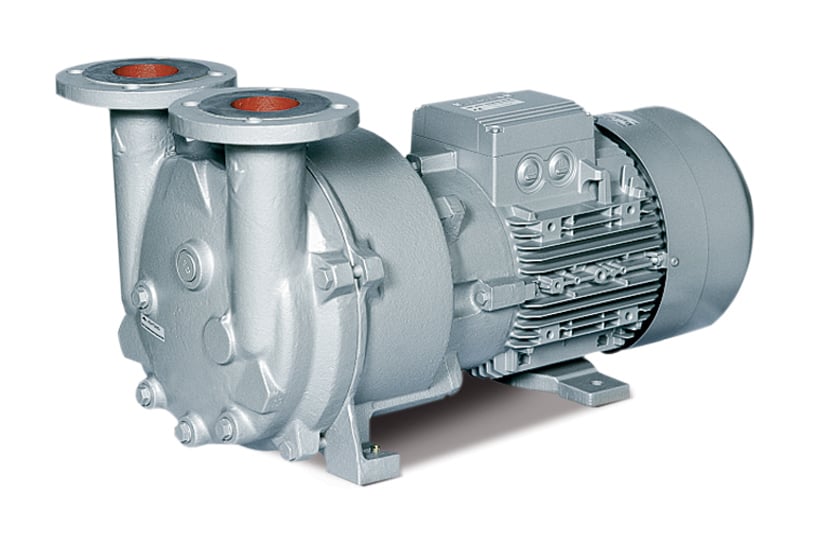

Elmo Rietschle's L-Series Compact

Heavy Duty Service Liquid Ring Vacuum Pumps

Pinnacle Industries has partnered with Elmo Rietschle to offer liquid ring vacuum pumps for your toughest applications. Elmo Rietschle liquid sealed industrial vacuum pumps meet and overcome industrial challenges. Your average liquid sealed vacuum pump can suffer considerable reduction in performance when faced with lime scale or abrasion brought on by extreme conditions like humid and wet processes. German designed and engineered, Elmo Rietschle L-Series liquid ring industrial vacuum pumps are up to the test with high-quality materials. Stainless steel and ceramics ensure the utmost reliability and constant operating characteristics allowing years of maintenance free operation.

Whether processing high air temperatures, gases or chemicals, Elmo Rietschle liquid ring vacuum pumps vacuum pumps can handle the toughest applications. Elmo Rietschle offers construction materials to handle all of your liquid ring vacuum pump applications.

Reliable and Economical:

Elmo Rietschle L-Series compact liquid ring vacuum pumps and liquid ring compressors are both reliable and economical. Your technicians will find that they last longer and can be trusted to perform more consistently than modular pumps. Ultimately, Elmo Rietschle quality will considerably reduce your operating costs.

Safe and Resilient:

Pinnacle Industries recognizes your need for safety in the workplace. You will value our liquid ring pumps for their safe and reliable functionality despite extreme conditions and humidity. Elmo Rietschle L-Series compact industrial liquid ring vacuum pumps are corrosion resistant due to quality crafted stainless steel shafts.

No more Limescale:

Beat Limescale with L-Series industrial liquid ring vacuum pump housings with a unique ceramic internal coating that prevents your pumps from calcifying due to fluid deposits. Elmo Rietschle developed the special coating for its liquid ring pumps and liquid ring compressors in cooperation with expert partners to meet high demands. The benefit: years of optimal performance at a low maintenance cost.

Advantages:

- Optional materials of construction

- Maximum abrasion resistance

- Excellent corrosion resistance

- No deposits and lime scale

- Excellant for high temperature applications

- Liquid Ring vacuum pump systems available

Applications:

- Asphalt-thickening machines (steamrollers)

- Ceramics

- Corrosion protection for water pipes

- Drying systems

- Dust extraction in the mining industry

- Environmental

- Exhausts in sewage treatment plants

- Extracting oil residues

- Food & Beverage

- Meat and poultry processing

- Lifting and handling

- Material damping in the textile industry

- Medical

- Packaging

- Plastics

- Steam turbines and motors

- Systems for cleaning and removing fat from particles in hydrocarbons (AIII)

- Systems to lower the water table

- Gas and high temperature processing

- Plastic extruder gas ventilation

- Chemical processing

- CNC router table vacuum pumps

- Liquid pump priming

L-Series Vacuum Pumps

Operating Principle L-Series Liquid Ring Vacuum Pump

L-Series liquid ring pump systems excel where suction capacities are required in a limited amount of space. Liquid ring pumps are often used for sterilizer functions, chemicals, in high temperatures or in medical or laboratory equipment.

The systems involve a single impeller as the only moving part inside a sealed liquid ring vacuum pump chamber. The rotating liquid ring seals the impeller within the liquid ring pump on the front and seals its blades against one another. That impeller rotates without contacting the liquid ring pump casing as a rotating liquid ring seals it in on the front and keeps the blades against one another. Liquid is permanently sucked into the compression chamber in order to keep the ring stable and is then output along with the conveyed gas.

The one-sided, just off center arrangement of the impeller within the liquid ring pump casing creates variable compression chambers between the impeller blades during rotation, which causes the conveyed gas to be compressed within a full revolution. Since the pumps always create a pressure difference during operation, they can also be used as compressors when pumping gas from the surrounding atmosphere.

The L-BV liquid ring pump product line features a patented discharge-air cooling system which returns the condensate to the operating liquid.

L-BL2

The L-BL2 range comprises compact plug-and-play systems for easy on-site installation. The pumps are air-cooled, 100 % oil-free and do not require additional water during operation. In addition, the vacuum pumps provide a much higher resistance to water and steam than alternative systems. Thanks to contact-free compression, they are virtually wear-free in operation and need no periodic maintenance. The patented discharge-air cooling system ensures that the pumps will not heat up by more than 15 K above room temperature. The pumps work reliably in continuous operation and are steam resistant and insensitive to condensation of the pumped air.

Pump units

Vacuum power units of the L-BL2 Split type are standardized liquid ring pump circulation systems with patented exhaust air cooling for large volume flows. A considerable amount of the water contained in the cool exhaust air condenses, remains in the system, and is thus available as operating water. As a result many applications no longer require additional operating water. Our low-maintenance vacuum pumps have been tried and tested for many years in numerous industrial applications. A comprehensive product range of accessories is available for this pump type.

Split

The L-BL2 split range family of pumps allow the user to take advantage of the L-BL technology in applications where higher air volume is needed or for special process requirements. They are suitable for applications involving aggressive suction materials and can also be implemented e.g. in the food & beverages industry where they are available in versions made entirely of stainless steel. We also sell versions equipped with all the valves including tubing required for integration into a CIP cleaning process. Air-to-water heat exchangers or plate heat exchangers are also on offer.

The impeller is the only moving part inside the pump. It rotates without contact within the pump casing. A rotating liquid ring seals the impeller on the front and seals its blades against one another. In order to keep the liquid ring stable, liquid is also permanently sucked into the compression chamber and is output together with the conveyed gas.

The excentrical arrangement of the impeller within the casing creates variable compression chambers between the impeller blades during rotation, which causes the conveyed gas to be compressed within a full revolution.Since the pumps always create a pressure difference during operation, they can also be used as compressors when pumping gas from the surrounding atmosphere.

The L-BV product line features a patented discharge-air cooling system which returns the condensate to the operating liquid.

Volume flow:

- 27 to 1,200 m³/h

- 15.9 to 705.9 cfm

L-BV3

These liquid ring vacuum pumps are convincing – whether they are used for sterilizers or for medical/laboratory equipment, they excel where extremely small suction capacities are required within a minimum of space. With a suction volume of up to 11 m³/h, these little workhorses are particularly quiet and consume very little water. It goes without saying, of course, that the L-BV3 can also convey suction-side steam and liquids.

The L-BV3 features an unusually compact design: constructed in our tried-and-tested modular design, it has extremely space-saving dimensions. And also in respect to quality, the L-BV3 leaves no wishes unfulfilled: corrosion-resistant materials, reinforced bearings and a stainless steel shaft in the pump section all consistently ensure safe and efficient operation even under high loads.

Volume flow:

- 10 to 11 m³/h

- 5.9 to 6.5 cfm

L-BV5

The block pumps in the L-BV5 family are characterized by a very high suction volume of up to 600 m³/h with suction pressures of up to 33 mbar abs. and are primarily used for applications with large quantities of liquids. The L-BV5 also simultaneously works as a condenser while suctioning condensable steam. This enables the suction volume to be doubled. The sound pressure level remains under 73 dB(A) and therefore fulfills even the strictest noise stipulations.

The single-stage compact construction of the L-BV5 reduces the space required for the installation of the pumps to around half that required by conventional modular machines. The pump can be easily installed in extruding machines and chemical systems, even when mounted to the underside of the tables. When developing these liquid ring pumps, Elmo Rietschle placed the focus on robustness and reliability. The L-BV5 can provide up to 20,000 hours of continuous operation without requiring an interruption for maintenance, even under the harshest conditions. Reinforced stainless steel shafts, continuously lubricated bearings and a coated pump housing prevent wear and tear caused by solids that are also sucked in, and guarantee constant performance, even after many years of use.

Volume flow:

- 90 to 600 m³/h

- 52.9 to 352.9 cfm

L-BV7

Our new L-BV7 liquid ring pumps are high-powered and multitalented machines which save space and up to 50 % in operating liquids. They can easily convey eight times the quantity of liquid. The monoblock construction of the L-BV7/L-BV2 far surpasses conventional modular pumps and is particularly suited for use in the plastics and medical industries.

The robustness and reliability is unparalleled in operation. The machines are available in various combinations of materials such as stainless steel, bronze, ceramic and cast iron with ceramic coating. This enables them to be tailored to the respective operating requirements and thus provides long-term resistance to erosion and corrosion. The entire L-BV range shines with quality: reinforced stainless steel shafts in the pump section and roller bearings with additional lubricant reservoir provide safe and maintenance-free operation even under heavy loads.

Volume flow:

- 27 to 145 m³/h

- 15.9 to 85.3 cfm

L-BV2

Our new L-BV7 liquid ring pumps are high-powered and multitalented machines which save space and up to 50 % in operating liquids. They can easily convey eight times the quantity of liquid. The monoblock construction of the L-BV7/L-BV2 far surpasses conventional modular pumps and is particularly suited for use in the plastics and medical industries.

The robustness and reliability is unparalleled in operation. The machines are available in various combinations of materials such as stainless steel, bronze, ceramic and cast iron with ceramic coating. This enables them to be tailored to the respective operating requirements and thus provides long-term resistance to erosion and corrosion. The entire L-BV range shines with quality: reinforced stainless steel shafts in the pump section and roller bearings with additional lubricant reservoir provide safe and maintenance-free operation even under heavy loads.

Volume flow:

- 27 to 145 m³/h

- 15.9 to 85.3 cfm

Contact Us