Elmo Rietschle's L-Series Pumps

Operating Principle L-Series Compressors

Compression in L-Series pumps follows the liquid ring principle. The impeller is the only moving part inside the pump. It rotates without contact within the pump casing. A rotating liquid ring seals the impeller on the front and seals its blades against one another. In order to keep the liquid ring stable, liquid is also permanently sucked into the compression chamber and is output together with the conveyed gas.

The excentrical arrangement of the impeller within the casing creates variable compression chambers between the impeller blades during rotation, which causes the conveyed gas to be compressed within a full revolution.Since the pumps always create a pressure difference during operation, they can also be used as compressors when pumping gas from the surrounding atmosphere.

The L-BV product line features a patented discharge-air cooling system which returns the condensate to the operating liquid.

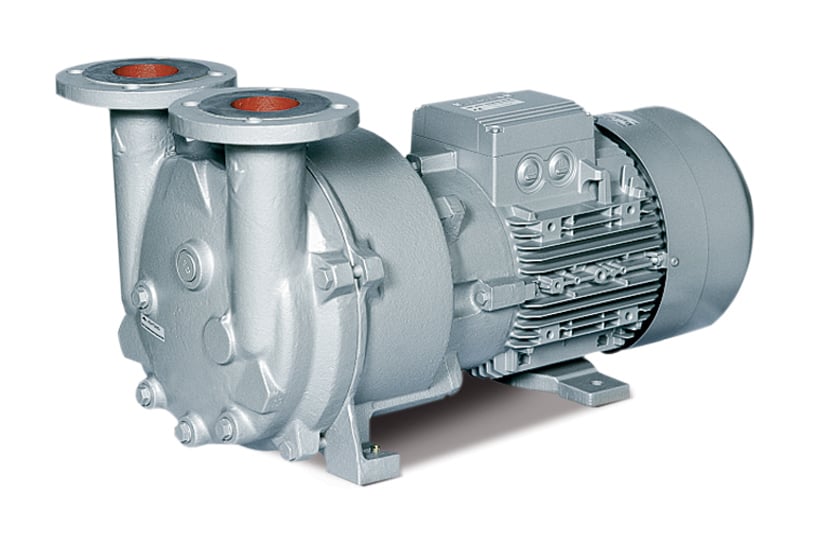

L-Series Compressors

L-BV7

Our new L-BV7 liquid ring pumps are high-powered and multitalented machines which save space and up to 50 % in operating liquids. They can easily convey eight times the quantity of liquid. The monoblock construction of the L-BV7 far surpasses conventional modular pumps and is particularly suited for use in the plastics and medical industries.

The robustness and reliability is unparalleled in operation. The machines are available in various combinations of materials such as stainless steel, bronze, ceramic and cast iron with ceramic coating. This enables them to be tailored to the respective operating requirements and thus provides long-term resistance to erosion and corrosion. The entire L-BV range shines with quality: reinforced stainless steel shafts in the pump section and roller bearings with additional lubricant reservoir provide safe and maintenance-free operation even under heavy loads.

Volume flow:

- 27 to 145 m³/h

- 15.9 to 85.3 cfm

L-BV2

The monoblock construction of the L-BV2 far surpasses conventional modular pumps and is particularly suited for use in the plastics and medical industries.

The robustness and reliability is unparalleled in operation. The machines are available in various combinations of materials such as stainless steel, bronze, ceramic and cast iron with ceramic coating. This enables them to be tailored to the respective operating requirements and thus provides long-term resistance to erosion and corrosion. The entire L-BV range shines with quality: reinforced stainless steel shafts in the pump section and roller bearings with additional lubricant reservoir provide safe and maintenance-free operation even under heavy loads.

Volume flow:

- 27 to 145 m³/h

- 15.9 to 85.3 cfm

L-BV5

The block pumps in the L-BV5 family are characterised by a very high suction volume of up to 600 m³/h with suction pressures of up to 33 mbar abs. and are primarily used for applications with large quantities of liquids. The L-BV5 also simultaneously works as a condenser while suctioning condensable steam. This enables the suction volume to be doubled. The sound pressure level remains under 73 dB(A) and therefore fulfils even the strictest noise stipulations.

The single-stage compact construction of the L-BV5 reduces the space required for the installation of the pumps to around half that required by conventional modular machines. The pump can be easily installed in extruding machines and chemical systems, even when mounted to the underside of the tables. When developing these liquid ring pumps, Elmo Rietschle placed the focus on robustness and reliability. The L-BV5 can provide up to 20,000 hours of continuous operation without requiring an interruption for maintenance, even under the harshest conditions. Reinforced stainless steel shafts, continuously lubricated bearings and a coated pump housing prevent wear and tear caused by solids that are also sucked in, and guarantee constant performance, even after many years of use.

Volume flow:

- 90 to 600 m³/h

- 52.9 to 352.9 cfm

Contact Us